Prinoth Snowgroomers

Innovative technology meets excellent performance

Advanced technologies combined with forward-looking design. Prinoth – the name has always been synonymous with groomers engineered to the very highest standards.

The perfect slope

PRINOTH guarantees amazing slopes all day long, in any snow condition. The slope finish is just perfect - your customers will notice.

One vehicle platform

Innovative technology, pioneering design by Pininfarina and one common vehicle platform – these are PRINOTH's snow groomers.

Highest performance

PRINOTH guarantees best area coverage and prepared slopes per hour. Our vehicles are designed for cost efficiency and economy.

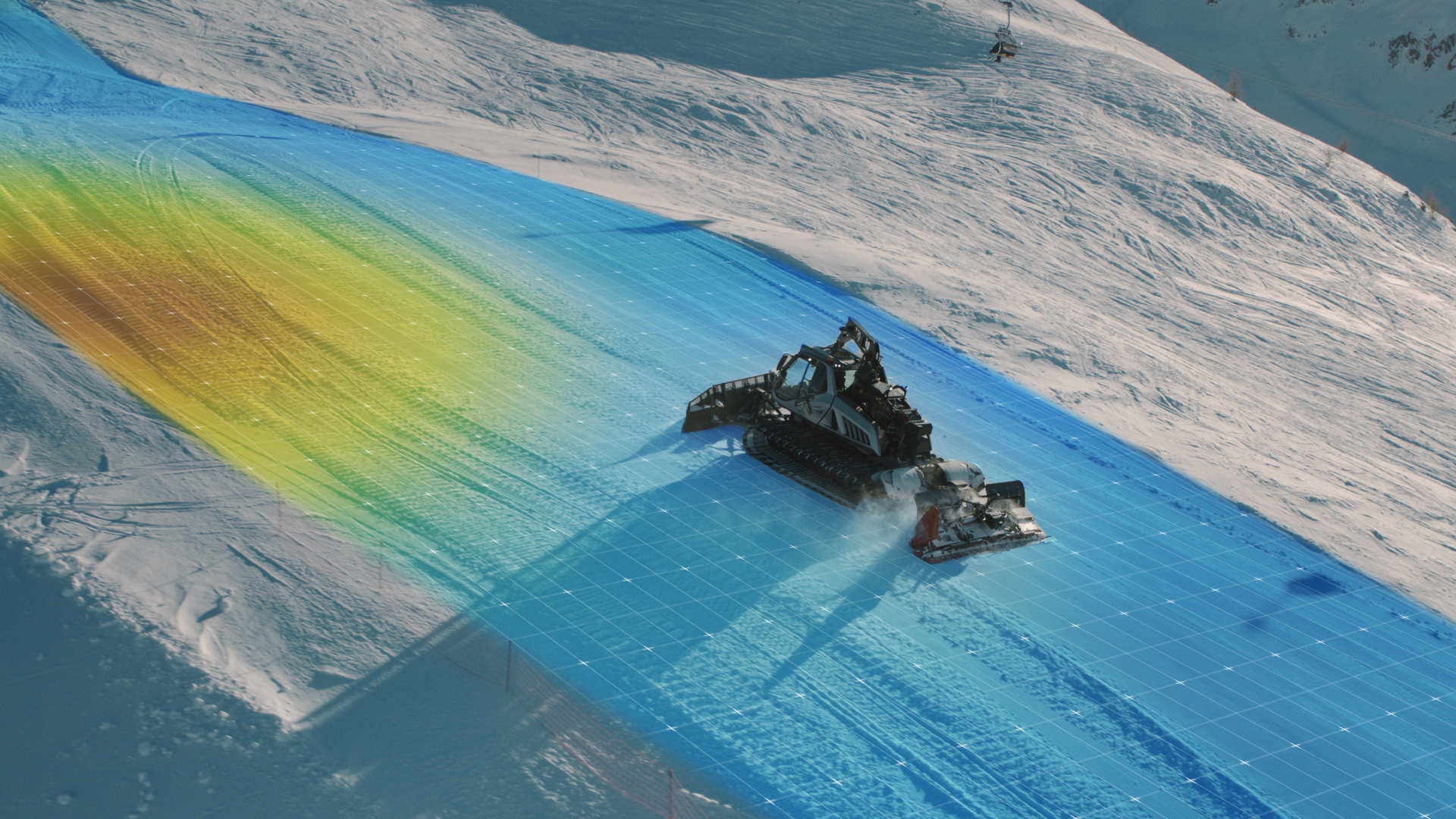

Proven digital solutions

PRINOTH snow measurement and fleet management systems are the most sold in the world. Manage the data of your entire ski resort easily.

NEW LEITWOLF - LEITWOLF X

-

With a state-of-the-art cockpit design, the powerful MTU stage V engine, and a brand new look, LEITWOLF truly is leader of the pack.

A perfect finish

A class of its own, PRINOTH’s patented parallel offset of the tiller slides up to 45 cm outside of the track footprint while staying in line with the direction of the LEITWOLF. This allows for a perfect finish when overlapping or operating next to obstacles.

Clean and powerful

Power through and through coupled with low fuel consumption and low emissions — the MTU in-line 6 engine offers it all. The impressive 530 HP engine with a maximum torque of 2600 Nm makes LEITWOLF the most powerful snow groomer in the world. Equally as important for the operation, due to MTU’s cooled exhaust gas aftertreatment, emissions are kept to a minimum.

Fast and efficient

Perfect slopes with minimum effort—this is LEITWOLF. With a working width of 4.5 m (14.8 ft.), the patented parallel offset of the tiller and widest blade on the market, LEITWOLF grooms the most surface in the shortest time. This means more quickly prepared slopes using less fuel—saving both time and money.

Comfortable and practical

The all-new cockpit design has increased leg room, upgrades to the joystick and a totally new 12” touchscreen display. The joystick has been optimised to make handling straight-forward. Incorporated is a joystick-in-joystick feature that enables operation of the blade using only the thumb. This provides simultaneous movement of all blade functions, enabling perfect slopes and the construction of challenging park elements. Moreover, the entire joystick can be adjusted to fit exactly the operators preferred position, making long hours of operation comfortable and strain free. The 12” touchscreen display allows for quicker access to the most important features. With a single touch operators can switch between options—whether it’s adjusting the lights, using the rear camera or checking the position of the tiller the new display has it covered.

Traction and maneuverability

Exclusive to LEITWOLF, the adjustable suspension gives more control in challenging conditions. By raising the LEITWOLF’s suspension, the front and rear of the tracks are raised off the ground. The result is less track in contact with the snow. This makes turning tight corners easy and stress less

By lowering the suspension, the increased contact of the tracks with the snow maximizes traction. This boosts performance when grooming uphill, downhill and pushing large amounts of snow. Total control at the touch of a button.

Control and Stability

Climb better with the optimised winch. Through repositioning the AUTOMATIC winch, the center of gravity has been lowered and moved forward. This distributes the vehicle weight more evenly giving it maximum traction. Additionally, the optimal placing of the winch enables a stable driving direction to be maintained, especially when pulling sideways.

The impressive pulling force of 4.5 tonnes can be controlled either manually or automatically, enabling operators of all skill levels to use the winch as efficiently as possible. At the same time, the ECO mode can be enabled to save energy by reducing the pulling force. And, for easy and intuitive winching, the operator can choose between giving more power to the winch or to the operation speed of the vehicle. Fitting perfectly to the operator’s preference.

LEITWOLF X

Build the world’s best parks. Features both in and out make LEITWOLF X the snow groomer of choice for demanding parks. For the best all round visibility, the operator’s seat is centred in the middle of the cockpit and together with the integrated rear-view camera give a view of every angle. Additionally, the increased range of movement of the blade and tiller, the custom-designed park blade with side cutters, and the inclinometer enable perfect preparation of park elements in the tightest spots.

HUSKY - HUSKY X

-

Versatility: in the preparation of slopes, parks, cross-country ski and snowmobile trails, and in passenger transport

The HUSKY, a versatile and ingenious vehicle packing plenty of power, boasts dimensions of 5110mm x 2445mm x 2655mm (201 in. x 96 in. x 105 in.) and is powered by a four-cylinder engine generating 231 HP (170 kW). Complying with Stage V/Tier 4 final exhaust emission standards, it is ideal for use at smaller ski resorts, parks and indoor ski slopes due to its low emission values and extreme maneuverability. It is also popular for use in preparing snowmobile trails and cross-country ski trails and yet it is capable of so much more: Transporting materials and people in difficult terrain is a breeze thanks to the HUSKY.

The NORDIC LINER from PRINOTH is especially versatile and easy to use. Its two track setting plates and tillers can be individually activated.

From luxurious to practical: The new passenger transport cabin

With its optional passenger cabin, the HUSKY safely and easily transports up to nine passengers with skis or a European pallet of material to the desired location. The passenger cabin’s panoramic glass windows enable panoramic mountain views while the leather seats, heating and climate control ensure maximum comfort. Designed by Pininfarina, the PRINOTH passenger cabin is also aesthetically attractive, transforming any excursion into an unforgettable outdoors experience. Whether optimally grooming the slopes or transporting passengers in luxury, the HUSKY does it all.

The agile & flexible park expert: The X-version of the HUSKY

With an increased vertical blade movement, up to 19˚ (8˚ up and 11˚ down) more than on a standard unit, the HUSKY X allows better control over the creation and maintenance of jumps, landings and other park features. Adapted hydraulic pumps ensure optimal response of the blade for that precise maneuverability every park operator is looking for. The HUSKY X is undoubtedly the most agile park builder in the industry.

Taming the snowmobile trails: The ideal task for the HUSKY

In its snowmobile trail groomer configuration, the HUSKY shines by providing the ideal work tool for preparing and maintaining snowmobile trails. The HUSKY’s narrow width, exceptional torque and comfort features combined to the array of trail grooming accessories that can be added make it the perfect machine to handle any snowmobile trail system out there.

NEW BISON - BISON X

-

With a state-of-the-art cockpit design, Caterpillar’s cleanest stage V engine, and a brand new look, BISON is both the most powerful and comfortable snow groomer in its class.

Clean and powerful

Low fuel consumption, low emissions and more powerful than ever. The 422 HP, in-line 6 Caterpillar engine boasts an impressive maximum torque of 1900 Nm at an optimal 1400 RPM, meaning power is delivered from the get go. The aftertreatment system decreases exhaust emissions making it the cleanest engine of its class used in snow groomers. With low maintenance and operating costs, the Caterpillar engine is the perfect choice for a demanding snow groomer such as the BISON.

Comfortable and practical

The increased leg room of the cockpit and the all-new control unit with upgrades to the joystick and a large12” touchscreen display make for an unrivalled driving experience. The joystick has been optimised to make handling straight-forward. Incorporated, is a joystick-in-joystick feature that enables operation of the blade using only the thumb. This provides simultaneous movement of all blade functions, enabling perfect slopes and the construction of challenging park elements. Moreover, the entire joystick can be adjusted to fit exactly the operator’s preferred position, making long hours of operation comfortable and strain free.

Control and Stability

The 12” touchscreen display allows for quicker access to the most important features. With a single touch operators can switch between options—whether it’s adjusting the lights, using the rear camera or checking the position of the tiller the new display has it covered.

The AUTOMATIC winch supports the BISON in traction and stability. Due to the optimal position of the winch pivot point the BISON maintains a stable driving direction when pulling sideways. Additionally, the impressive pulling force of 4.5 tonnes can be controlled either manually or automatically, enabling operators of all skill levels to use the winch as efficiently as possible At the same time, the ECO mode can be enabled to save energy by reducing the pulling force. And, for easy and intuitive winching, the operator can choose between giving more power to the winch or to the operation speed of the vehicle. Fitting perfectly to the operator’s preference.

BISON X

Build the world’s best parks. Features both in and out make BISON X the snow groomer of choice for parks big and small. For the best all round visibility, the operator’s seat is centred in the middle of the cockpit. For increased visibility, the electric sliding-seat function enables the operator to move the seat to the left of the machine. Additionally, the range of movement of the blade and tiller, the custom-designed park blade with side cutters, and the inclinometer enable perfect preparation of park elements in the tightest spots.

LEITWOLF - LEITWOLF X

-

Maximum slope quality with minimum effort: this is the motto of the LEITWOLF. With its unrivalled 530 HP, it is the most powerful snow groomer in the world. With a working width of 4.5 m (14.8 ft.) and the patented parallel offset of the tiller, it handles the largest slopes in the shortest time. Equipped with the AUTOMATIC winch, even slopes with a gradient of 45% are child’s play.

The PRINOTH LEITWOLF has proven itself on the slopes of this world and earned the trust of the many prestigious ski resorts. With its superior and proven technology, it convinces operators and managers alike. A LEITWOLF does not make empty promises, it delivers a clear statement and exceptional results.

Clean Motion Vehicles

Zero Emission. Perfect slopes.

Motivated by the PRINOTH CLEAN MOTION philosophy, we have revolutionized snow grooming vehicle technology. Our electric HUSKY eMOTION and hydrogen-powered LEITWOLF h2MOTION - with both fuel cell or internal combustion engine - take sustainable snow grooming to the next level.

The future has arrived.

DISCOVER OUR ZERO-EMISSION MODELS

HUSKY eMOTION

-

SUSTAINABILITY

Ski resorts and cross-country centers around the world are setting new targets to reduce their carbon footprint. The electric HUSKY eMOTION is a zero emission snow groomer that can help meet these goals. Make a difference, make it a HUSKY eMOTION.

POWER THROUGH AND THROUGH

The electric motor delivers 245 hp with 1,000 Nm of torque from the very start. This means performance from the second the vehicle is put into drive. Only an electric snow groomer can offer this amount of torque from the get go. With a maximum running time of 3 hours, most cross-country tracks and small slopes can be prepared before recharging.

CABIN COMFORT

Operation has never been as easy. PRINOTH’s acclaimed operator concept with its 12” touch-screen display, ergonomic operating positions, and joystick in joystick function enables easy and efficient handling—helping to create the perfect finish.

VERSATILITY

Whether it’s laying cross-country tracks, grooming slopes or preparing trails, the HUSKY eMOTION is as versatile as it is powerful. Equipped with the NORDIC LINER and its two-track setting plates, the eMOTION lays smooth, cross-country tracks that last.

LEITWOLF h2MOTION

-

he LEITWOLF h2MOTION is a concept vehicle that combines performance with sustainability. The hydrogen snow groomer has been developed with two different powertrains—a fuel cell and an internal combustion engine. The hydrogen is stored in tanks that are mounted on the back of the machines allowing for running times of up to four hours. With a state-of-the-art cockpit design and all the best features from our flagship snow groomer the LEITWOLF h2MOTION paves the way for sustainable winter sports.

LEITWOLF h2MOTION with hydrogen fuel cell (2020)

The concept vehicle is the world’s first snow groomer powered by an electric motor that receives its energy from a hydrogen fuel cell. The emission-free machine has an output of 544 hp (400 kW) which is even more powerful than our classic diesel model.

LEITWOLF h2MOTION with hydrogen internal combustion engine (2022)

The world’s first snow groomer powered by a hydrogen internal combustion engine is carbon-free. Being similar to a diesel setup it is very familiar for operators and technicians. The 13 liter, six-cylinder engine delivers 460 hp (338 kW) and 2,000 Nm of torque.

SNOW GROOMERS

For anywhere in the world

PRINOTH has long been a synonym for top quality snow groomers. More than 50 years of experience, innovation and development lies behind PRINOTH’s successful history.

Sustainable slope technology

PRINOTH trades responsibly. A sustainable business model is the precondition for all of the company’s activities. PRINOTH’s aim is to supply its international clients with highly efficient and high-quality vehicles, together with an unforgettable product experience, with reliability being the watchword. PRINOTH makes its product and investment decisions in a way, which is geared towards its clients’ needs. To keep up with changing requirements requires passion as well as competence and speed.

The ideal workplace

As global leaders in technology, comfort and design, our snow groomers form the ideal workplace. The ergonomic cabin layout in our snow groomers, with central seat, guarantees a comfortable workplace with excellent all-round vision.

The world's most comprehensive range

Regardless of whether for a ski run, cross-country trail, funpark or transport. PRINOTH has the right model for every requirement. Choose from the world's widest range of snow groomers. We can help you make your choice and will be happy to advise you in your search for the appropriate vehicle. PRINOTH regards itself as an expert partner with top service and close customer relations the highest priority.

Facts

Innovation and technology leader

50 years of experience

Sustainability & environmental protection

Pininfarina Design

A very comprehensive range

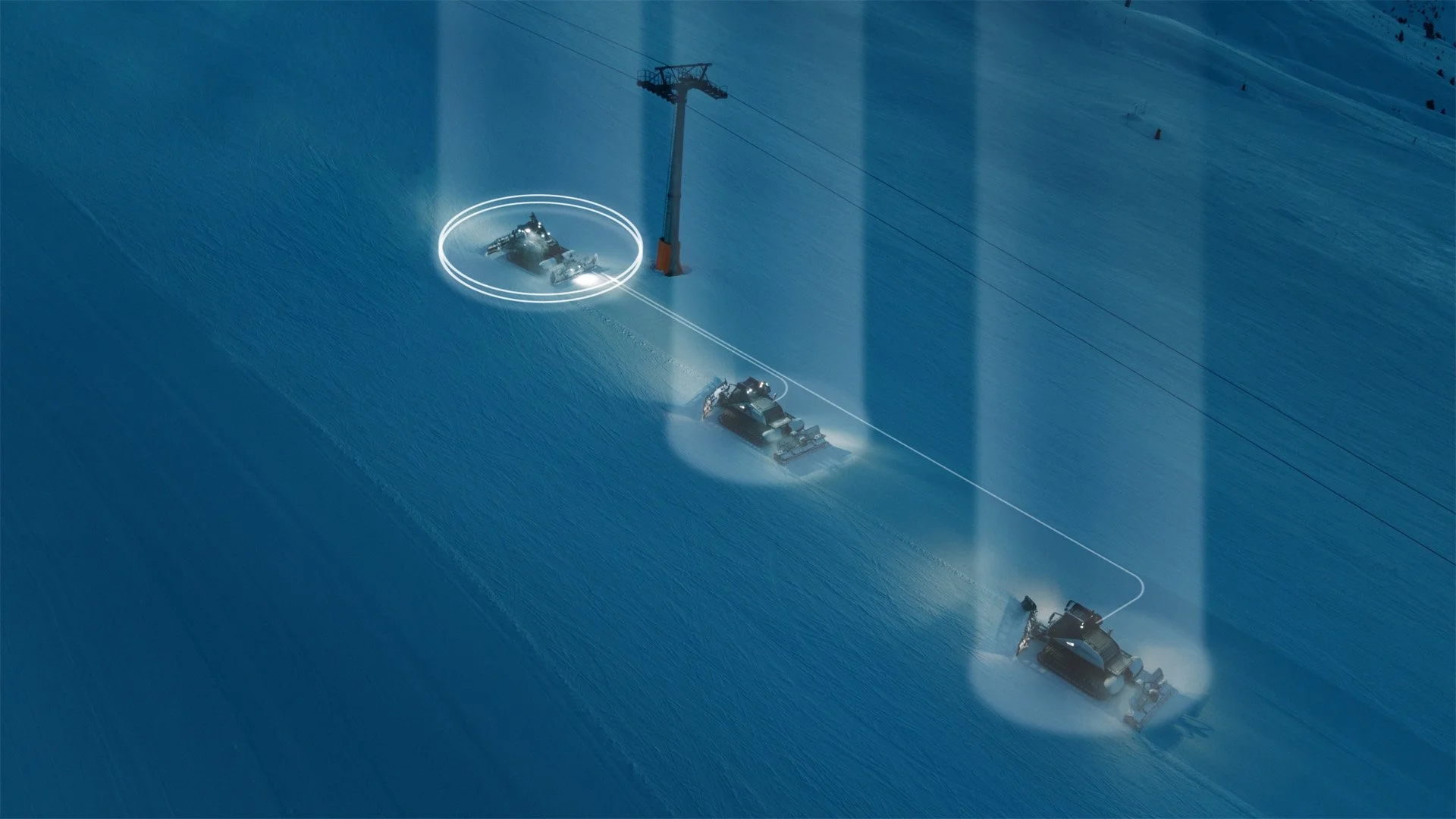

Prinoth Connect

PRINOTH Connect is our commitment to improving everyday work life for people operating our machines and employed in ski resorts. We do this through technology that connects you with your colleagues and your vehicles. This enables up-to-date information on your equipment whenever and wherever you need it. The benefits of our connected services are easier to manage, cost efficient and more sustainable vehicle operations.

No1 in Slope Grooming

Prinoth – for perfect pistes. Ensure optimum piste conditions all day long. Our PRINOTH tiller guarantees you the best result. In any snow conditions. Your customers will notice it as well and reward you with more frequent visits to your slopes, right through until it gets dark, even into the warmer spring months.

-

Perfect pistes

You can rely on a perfect piste whatever the snow conditions.

-

Efficiency

Improved efficiency thanks to major savings in time and costs for greater economy.

-

Saving costs

Saving money thanks to reduced Total Cost of Ownership. Your vehicle is designed for cost efficiency and economy.